Description

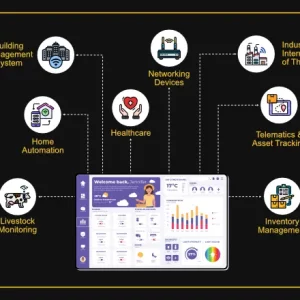

Our Digital Twin Implementation Services create virtual replicas of physical assets, processes, or systems, enabling real-time insights, simulation, and performance optimization across industries. By integrating IoT data, sensor streams, and machine learning algorithms, digital twins help predict outcomes, detect faults early, and simulate operational changes in a risk-free environment. We start by identifying critical assets (e.g., equipment, buildings, vehicles) and capturing their behavioral and sensor profiles. Using platforms like Azure Digital Twins, Siemens Mindsphere, or custom-built twins via Unity/Unreal, we map the physical asset’s structure, dynamics, and environmental interactions. Our implementation supports 3D visualization, real-time monitoring, historical playback, and KPI tracking dashboards. We also integrate predictive analytics to forecast maintenance needs, optimize energy usage, or simulate process improvements. For enterprises, we align twins with PLM/ERP systems for lifecycle management. Use cases range from smart manufacturing and HVAC systems to digital city infrastructure and predictive fleet management. Post-deployment, we provide continuous model refinement and cloud integration. Digital twins bridge the physical and virtual worlds—empowering innovation, reducing downtime, and enhancing strategic decision-making through advanced digital intelligence.

Asiya –

“The digital twin implementation services have revolutionized the way I understand and optimize my business operations. Being able to simulate scenarios and monitor assets in real-time has provided invaluable insights, leading to significant improvements in efficiency and decision-making. The expertise in IoT and AI was evident, and the solutions were tailored perfectly to my specific needs, despite me working solo. This service is an absolute asset for any business looking to leverage the power of digital twins.”

Janet –

“Implementing digital twin technology has significantly boosted my business operations. The services provided have enabled me to simulate scenarios, monitor assets in real-time, and predict potential issues before they arise. This has led to improved efficiency, reduced downtime, and better decision-making. A truly valuable asset for any business looking to leverage the power of IoT and AI.”

Joel –

“The digital twin implementation services have been invaluable in optimizing my business processes. Their expertise in IoT and AI allowed them to create a virtual replica of my physical systems, which has significantly improved simulation, monitoring, and predictive analysis. This service has undeniably boosted my business’s efficiency and given me a competitive edge.”

David –

“These IT services have been invaluable in helping me improve my business through digital twin implementation. The ability to simulate and monitor my physical assets virtually using IoT and AI has allowed for predictive analysis that I simply couldn’t achieve before. This has truly transformed my operational efficiency and provided insights that have directly impacted my bottom line. It’s been a great experience working with them.”

Confidence –

“The digital twin implementation services have been instrumental in transforming my business. Their approach to replicating my physical systems virtually using IoT and AI has provided invaluable insights through simulation and real-time monitoring. I can now proactively analyze my assets and make informed decisions, leading to significant improvements in efficiency and predictive capabilities. This technology has greatly benefited my operations.”